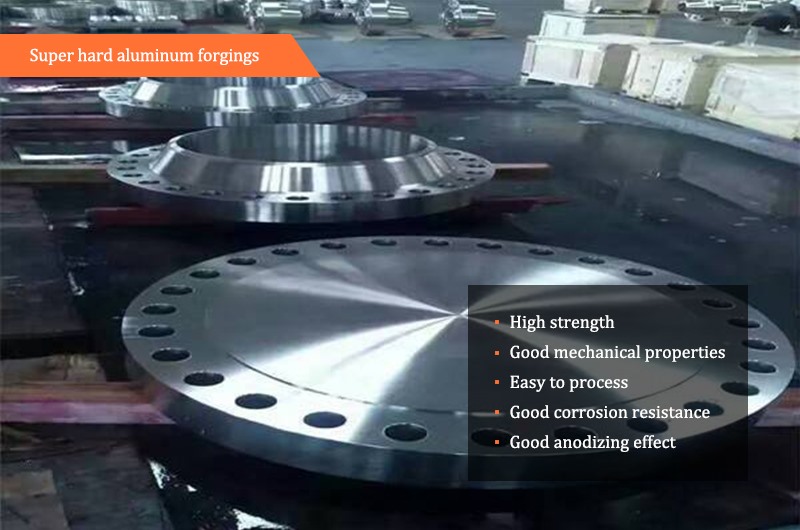

Introduction of Super hard aluminum forgings

The 7-series aluminum alloy belongs to the Al-Zn-Mg-Cu series super-hard aluminum. The Super hard aluminum forgings- is an ultra-high-strength deformed aluminum that has been used in the aircraft manufacturing industry in the late 1940s and is still widely used in the aviation industry. alloy. It is characterized by good plasticity after solution treatment, particularly good heat treatment strengthening effect, high strength below 150 ° C, and particularly good low temperature strength; poor welding performance; Protected handling use. Dual-stage aging can improve the alloy's resistance to stress corrosion cracking. The plasticity in the annealed and just quenched state is slightly lower than that of 2A12 in the same state. It is slightly better than 7A04. The static fatigue of the plate is sensitive to notch, and the stress corrosion performance is better than that of 7A04. The density is 2.85g/cm3.

Features of Super hard aluminum forgings

1. High-strength heat-treatable alloy.

2. Good mechanical properties.

3. Good usability.

4, easy to process, good wear resistance.

5. Good corrosion resistance and oxidation resistance.

6. Good anodic oxidation effect.

The use of Super hard aluminum forgings-

Super hard aluminum forgings- are used in aerospace industry, blow molding (bottle) molds, ultrasonic plastic welding molds, golf ball heads, shoe molds, paper molds, foam molding molds, wax molds, templates, fixtures, machinery and equipment , mold processing and other corrosion-resistant high-stress structural parts.

The 7-series aluminum alloy belongs to the Al-Zn-Mg-Cu series super-hard aluminum. The Super hard aluminum forgings- is an ultra-high-strength deformed aluminum that has been used in the aircraft manufacturing industry in the late 1940s and is still widely used in the aviation industry. alloy. It is characterized by good plasticity after solution treatment, particularly good heat treatment strengthening effect, high strength below 150 ° C, and particularly good low temperature strength; poor welding performance; Protected handling use. Dual-stage aging can improve the alloy's resistance to stress corrosion cracking. The plasticity in the annealed and just quenched state is slightly lower than that of 2A12 in the same state. It is slightly better than 7A04. The static fatigue of the plate is sensitive to notch, and the stress corrosion performance is better than that of 7A04. The density is 2.85g/cm3.

Features of Super hard aluminum forgings

1. High-strength heat-treatable alloy.

2. Good mechanical properties.

3. Good usability.

4, easy to process, good wear resistance.

5. Good corrosion resistance and oxidation resistance.

6. Good anodic oxidation effect.

The use of Super hard aluminum forgings-

Super hard aluminum forgings- are used in aerospace industry, blow molding (bottle) molds, ultrasonic plastic welding molds, golf ball heads, shoe molds, paper molds, foam molding molds, wax molds, templates, fixtures, machinery and equipment , mold processing and other corrosion-resistant high-stress structural parts.