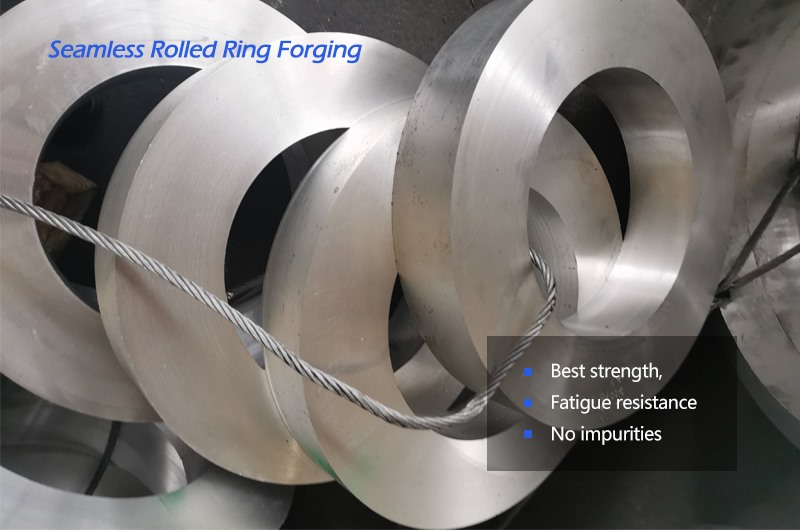

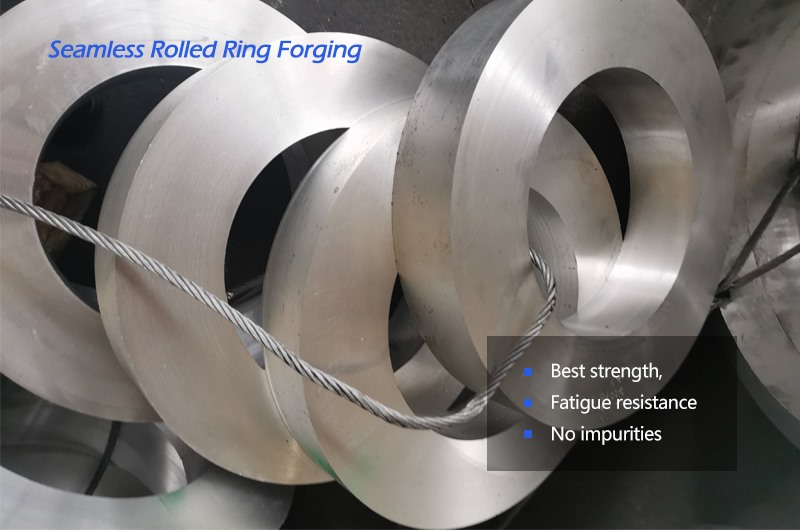

Seamless Rolled Ring Forging provides your forgings with optimum strength, fatigue resistance and no inclusions. Henan Chalco creates shapes in a variety of sizes, from flat washers to tall cylindrical aluminum parts. In addition, our seamless rolled rings can be delivered in rough and finished condition. We produce aluminum alloy rolled ring forgings of various specifications.

Advantages of Seamless Rolled Ring Forging

Seamless Rolled Ring Forging gives your forgings higher strength, fatigue resistance and inclusion-free. Profile-rolled ring forgings or near-net-shape rolled rings offer not only technical advantages, but also generally cost advantages, as the forging process produces a final product that requires fewer machining operations, reduced weight, and lower raw material costs.

Common applications of Seamless Rolled Ring Forging

Seamless Rolled Ring Forging is used for flanges or gear blanks and can be rough or fully machined. Because seamless rolled rings are a smooth product with concentricity and tight tolerances, they often form critical components in jet engines, jet turbines, helicopter gearboxes, paper mills, windmills and other extreme environments.

Process of Seamless Rolled Ring Forging

The process of Seamless Rolled Ring Forging begins with punching holes in thick or round aluminum billets. The workpiece is then heated, rolled and extruded into a ring. The ring rolling process orients the grain flow in a circumferential direction, providing greater fatigue and impact resistance.

Advantages of Seamless Rolled Ring Forging

Seamless Rolled Ring Forging gives your forgings higher strength, fatigue resistance and inclusion-free. Profile-rolled ring forgings or near-net-shape rolled rings offer not only technical advantages, but also generally cost advantages, as the forging process produces a final product that requires fewer machining operations, reduced weight, and lower raw material costs.

Common applications of Seamless Rolled Ring Forging

Seamless Rolled Ring Forging is used for flanges or gear blanks and can be rough or fully machined. Because seamless rolled rings are a smooth product with concentricity and tight tolerances, they often form critical components in jet engines, jet turbines, helicopter gearboxes, paper mills, windmills and other extreme environments.

Process of Seamless Rolled Ring Forging

The process of Seamless Rolled Ring Forging begins with punching holes in thick or round aluminum billets. The workpiece is then heated, rolled and extruded into a ring. The ring rolling process orients the grain flow in a circumferential direction, providing greater fatigue and impact resistance.