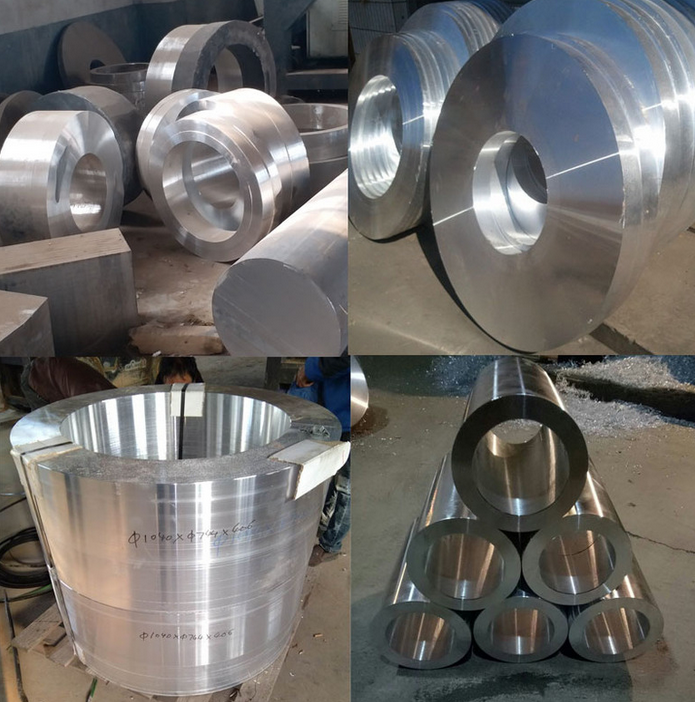

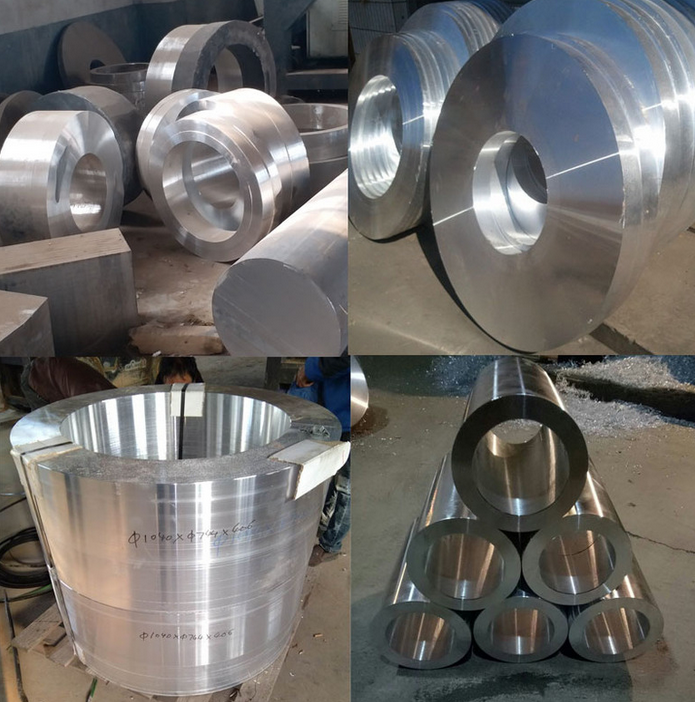

6151 Aluminum forgings forged product parts

6151 alloy T6 T652 aluminum forgings are generally used for forging crankshaft parts. Machine parts and rolling ring conducting mine and machine parts have good forgability, high strength and corrosion resistance. All parts requiring good forging performance, high strength and good corrosion resistance can be processed with this alloy.

Process characteristics

The annealing standard of 6151 alloy is 413â/ï¼2h~3hï¼. The cooling rate of 6151 alloy is not more than 27â/h. The alloy is cooled to 260 â with the furnace, and then air-cooled out of the furnace. Solid solution treatment temperature ï¼510â~525âï¼/4min, quenching in room temperature water, quenching in 65â~100â water for large forgings. Artificial aging codeï¼165â~175âï¼/ï¼8h~12hï¼. The hot working temperature ranges from 260 â to 480 â.

Mechanical property

The minimum mechanical properties of 6151 alloy are 50mm or 4D (d is sample diameter). 6151 alloy has no low temperature brittleness and can be used to process parts working at extremely low temperature. At 25 â, the tensile strength Rm = 330N/mm2, yield strength Rp0.2 = 298N/mm2, elongation A = 17%, and temperature drops to 200 â, the properties of 6151 alloy increase completely, reaching 395N/mm2, 345N/mm2 and 20%, respectively. The working temperature of 6151 alloy should not exceed 120 â.

Process characteristics

The annealing standard of 6151 alloy is 413â/ï¼2h~3hï¼. The cooling rate of 6151 alloy is not more than 27â/h. The alloy is cooled to 260 â with the furnace, and then air-cooled out of the furnace. Solid solution treatment temperature ï¼510â~525âï¼/4min, quenching in room temperature water, quenching in 65â~100â water for large forgings. Artificial aging codeï¼165â~175âï¼/ï¼8h~12hï¼. The hot working temperature ranges from 260 â to 480 â.

Mechanical property

The minimum mechanical properties of 6151 alloy are 50mm or 4D (d is sample diameter). 6151 alloy has no low temperature brittleness and can be used to process parts working at extremely low temperature. At 25 â, the tensile strength Rm = 330N/mm2, yield strength Rp0.2 = 298N/mm2, elongation A = 17%, and temperature drops to 200 â, the properties of 6151 alloy increase completely, reaching 395N/mm2, 345N/mm2 and 20%, respectively. The working temperature of 6151 alloy should not exceed 120 â.

| Alloy | Si | Fe | Cu | Mn | Mg | Cr | Ni | Zn | Ti | Ga | Others | Alu | |

| Each | Toal | ||||||||||||

| 6151 | 0.6--1.2 | 1.0 | 0.35 | 0.20 | 0.45--0.8 | 0.15--0.35 | -- | 0.25 | 0.15 | -- | 0.05 | 0.15 | Remainder |

| Tensile mechanical properties of 6151 aluminium alloy forgings | ||||

| Temper | Tension strength Rm/MPa | Prescribed plastic elongation strength Rp0.2/MPa |

Elongation A (%) |

|

| Mould forgings T6 | Axis parallel to grain flow direction | 303 | 225 | 14 |

| Axis parallel to grain flow direction | 303 | 255 | 6 | |

| Forged ring T6ãT652 | Radial direction | 303 | 255 | 5 |

| Axial direction | 303 | 241 | 4 | |

| Radial direction | 290 | 241 | 2 | |

| Type | Alloy | Projected areaï¼m2ï¼Or weightï¼kgï¼ | Temper | Standard |

| Free forgings | 5 series | ≤3000kg | OãF |

GBn223 ASTMB247 |

| 2ã6ã7 series | ≤3000kg | T6ãT4ãOãF | ||

| Mould forgings | 5 series | ≤2.5m2 | OãF | |

| 2ã6ã7 series | ≤2.5m2 | T6ãT4ãOãF |