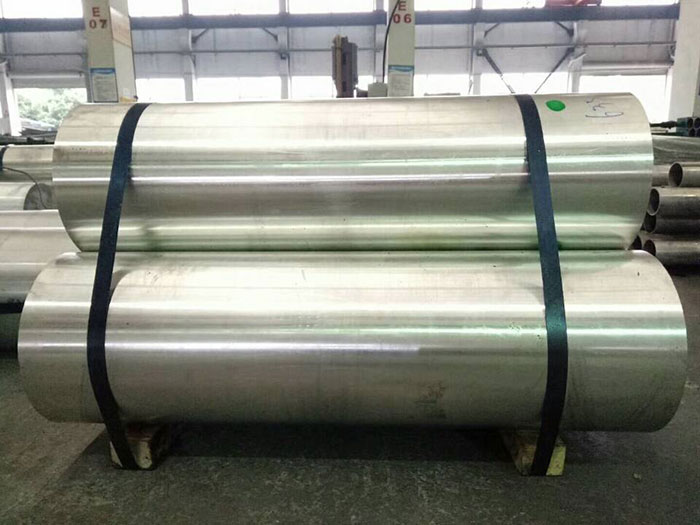

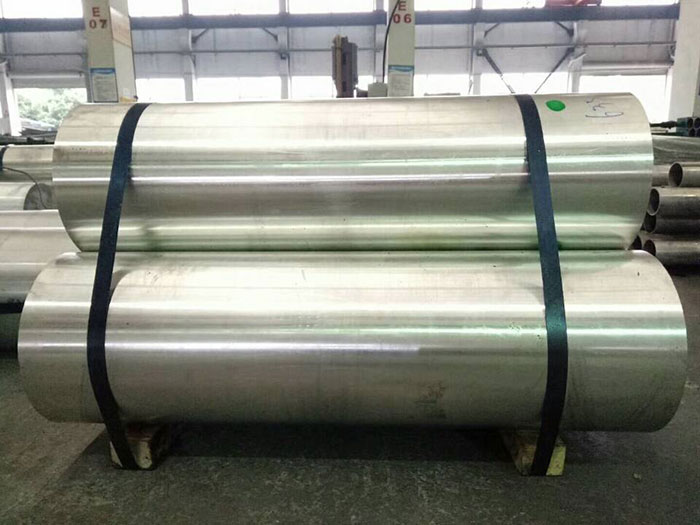

6061 Aluminum forgings forged product parts

6061 is a forged Al-Mg-Si alloy, which can be strengthened by heat treatment. The alloy has medium strength and high plasticity after solution heat treatment and aging treatment. The corrosion resistance and weldability of the alloy are better, but the corrosion resistance is slightly worse than that of 6A02 alloy, while the corrosion resistance of 6061 alloy clad aluminium products is significantly improved. Its machinability is medium to low.

6061 and 6063 Aluminium alloys are universal aluminium alloys in the world. They are widely used, especially in the construction industry. Modern high-rise buildings can not do without these two alloys. It is mainly used to produce light-weight structural parts such as doors, windows, benches, etc. It is also used to manufacture structural parts with high corrosiveness, good weldability and medium strength, such as structures of freight cars, trains and yachts, towers, pipelines, etc. Now it is widely used in forgings of automobiles, motorcycle control arms, wheel hubs, bicycle parts and so on.

For parts manufactured from rolling or drawing materials, it is advisable to heat them at 160 C for 18 h by artificial aging treatment, and for parts manufactured by extrusion or forging, it is advisable to heat them at 175 C for 8 h by artificial aging treatment.

6061 aluminium alloy has high technological plasticity under reheating condition, which is suitable for free forging and die forging to produce various forgings.

6061 and 6063 Aluminium alloys are universal aluminium alloys in the world. They are widely used, especially in the construction industry. Modern high-rise buildings can not do without these two alloys. It is mainly used to produce light-weight structural parts such as doors, windows, benches, etc. It is also used to manufacture structural parts with high corrosiveness, good weldability and medium strength, such as structures of freight cars, trains and yachts, towers, pipelines, etc. Now it is widely used in forgings of automobiles, motorcycle control arms, wheel hubs, bicycle parts and so on.

| Low Temperature Tensile Properties at Different Temperatures of 6061 alloy | ||||

| Temper | Temperature/â | Tensile strength Rm/MPa | Prescribed plastic elongation strength Rp0.2/MPa |

Elongation A (%) |

| T6ãT652 | -196 | 414 | 324 | 22 |

| -80 | 338 | 290 | 18 | |

| -28 | 324 | 283 | 17 | |

| 25 | 310 | 276 | 17 | |

| Tensile Properties at High Temperature at Different Temperatures of 6061 alloy | ||||

| Temper | Temperature/â | Tensile strength Rm/MPa | Prescribed plastic elongation strength Rp0.2/MPa |

Elongation A (%) |

| T6ãT652 | 100 | 290 | 262 | 18 |

| 150 | 234 | 214 | 20 | |

| 205 | 131 | 103 | 28 | |

| 260 | 51 | 34 | 60 | |

| 315 | 32 | 19 | 85 | |

| 370 | 24 | 12 | 95 | |

For parts manufactured from rolling or drawing materials, it is advisable to heat them at 160 C for 18 h by artificial aging treatment, and for parts manufactured by extrusion or forging, it is advisable to heat them at 175 C for 8 h by artificial aging treatment.

6061 aluminium alloy has high technological plasticity under reheating condition, which is suitable for free forging and die forging to produce various forgings.

| Type | Alloy | Projected areaï¼m2ï¼Or weightï¼kgï¼ | Temper | Standard |

| Free forgings | 5 series | ≤3000kg | OãF |

GBn223 ASTMB247 |

| 2ã6ã7 series | ≤3000kg | T6ãT4ãOãF | ||

| Mould forgings | 5 series | ≤2.5m2 | OãF | |

| 2ã6ã7 series | ≤2.5m2 | T6ãT4ãOãF |