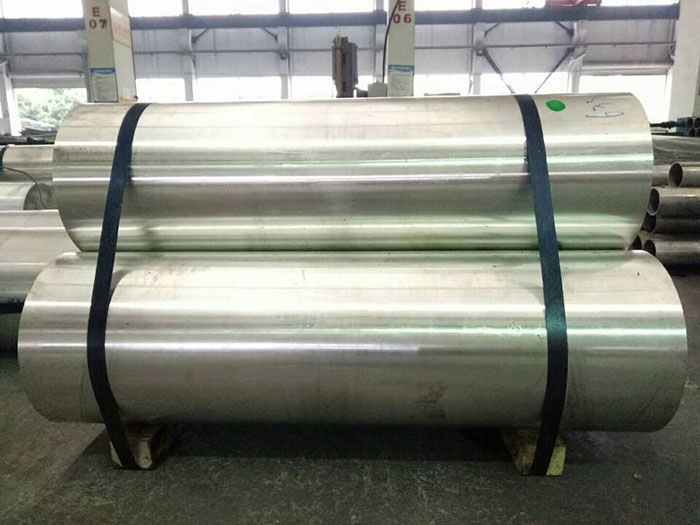

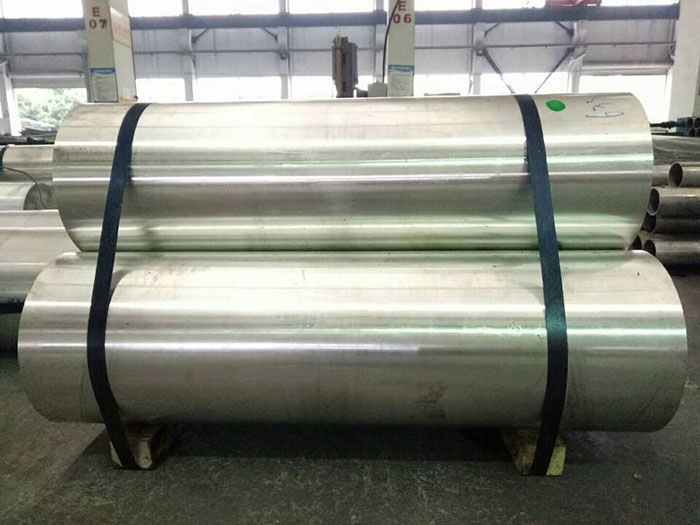

2A70 Aluminum forgings forged product parts

2A70 is a short heat-resistant Al-Cu-Mg-Fe-Ni alloy, which can be strengthened by heat treatment. The alloy has high heat resistance and service temperature of 200-250 â. The plasticity in hot state is high and there is no backlog effect. The corrosion resistance of the alloy is acceptable, but it has a profitable corrosion tendency. Its weldability is medium, suitable for resistance spot welding and seam welding, but the performance of arc welding and gas welding is poor. Its machinability is good.

2A70 aluminium alloy is used to manufacture piston of internal combustion engine and complex forgings working at 200-250â, such as compressor impeller, blower impeller, etc. Plate can be used as structure parts at above temperature, and its use is more extensive than another kind of heat-resistant forging aluminium 2A80.

2A70 aluminium alloy is prone to over-burning. The over-burning temperature is 545 â. Therefore, the heating temperature should be strictly controlled during forging and solution heat treatment. The Brinell hardness of the alloy is 130-139HBW under T6, 139HBW for small forgings and 130HBW for neutral forgings.

The forging performance of 2A70 aluminium alloy is good. It can be forged by hammer forging or by hydraulic press. The forging temperature of the alloy ranges from 450 to 350 â

2A70 aluminium alloy is used to manufacture piston of internal combustion engine and complex forgings working at 200-250â, such as compressor impeller, blower impeller, etc. Plate can be used as structure parts at above temperature, and its use is more extensive than another kind of heat-resistant forging aluminium 2A80.

| Mechanical properties of 2A70 aluminium alloy forgings specified in technical standards | |||||

| Temper | Direction | Tension strength Rm/MPa |

Prescribed plastic elongation strength Rp0.2/MPa |

Elongation A (%) |

|

| Free forgings | T6 | Portrait | 375 | ï¼ | 5.0 |

| T6 | Long transverse | 375 | ï¼ | 5.0 | |

| Die forgings | T6 | Portrait | 380 | 275 | 5.0 |

| T6 | Long transverse | 380 | 275 | 5.0 | |

| Tensile Properties of 2A70 Aluminum Alloy Forgings Stabilized at Room Temperature | |||||

| Temper | Stabilization treatment | Tension strength Rm/MPa | Elongation strength RP0.2/MPa |

Elongation A (%) |

|

| Temperature/â | Holding time/h | ||||

| Free forgings and Die forgings | 125 | 100 | 431 | 333 | 10 |

| 1000 | 431 | 333 | 8 | ||

| 10000 | 431 | 333 | 8 | ||

| 150 | 100 | 431 | 333 | 9 | |

| 1000 | 431 | 333 | 9 | ||

| 10000 | 431 | 333 | 9 | ||

| 175 | 100 | 421 | 353 | 8 | |

| 1000 | 402 | 353 | 8 | ||

| 10000 | 397 | 353 | 7 | ||

2A70 aluminium alloy is prone to over-burning. The over-burning temperature is 545 â. Therefore, the heating temperature should be strictly controlled during forging and solution heat treatment. The Brinell hardness of the alloy is 130-139HBW under T6, 139HBW for small forgings and 130HBW for neutral forgings.

The forging performance of 2A70 aluminium alloy is good. It can be forged by hammer forging or by hydraulic press. The forging temperature of the alloy ranges from 450 to 350 â

| Type | Alloy | Projected areaï¼m2ï¼Or weightï¼kgï¼ | Temper | Standard |

| Free forgings | 5 series | ≤3000kg | OãF |

GBn223 ASTMB247 |

| 2ã6ã7 series | ≤3000kg | T6ãT4ãOãF | ||

| Mould forgings | 5 series | ≤2.5m2 | OãF | |

| 2ã6ã7 series | ≤2.5m2 | T6ãT4ãOãF |