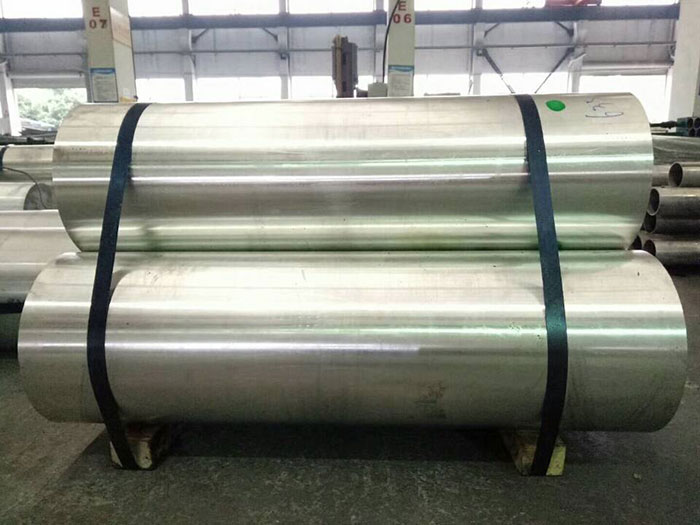

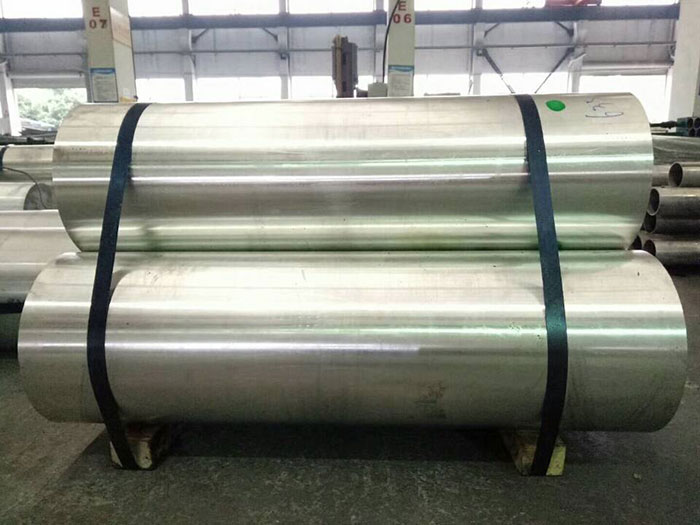

2A50 Aluminum forgings forged product parts

2A50 is a high strength forged Al-Cu-Mg-Si alloy, which can be strengthened by heat treatment. In hot state, it has high plasticity and is easy to forge and stamp. After solution treatment and artificial aging, it has high strength and good process plasticity, but it has extrusion effect, and its longitudinal and transverse properties are different. The corrosion resistance of the alloy is good, but there is a tendency of intergranular corrosion. The resistance spot welding and seam welding have good weldability, while the arc welding and gas welding have poor performance. Its cutting performance is good.

The time interval between solution quenching and aging strengthening of 2A50 aluminium alloy should be less than 6 h, the overburning temperature should be 545 â, and the forging temperature should be 470-370 â.

Because of its good casting properties, 2A50 aluminum alloy is suitable for producing large cross-section ingots. It is used as the blank of large hot-forged parts, such as partition frame, bracket and rocker arm of aircraft. It is also used to manufacture medium and small forgings and die forgings with complex shape and medium strength.

| Mechanical Properties of 2A50 Die Forgings and Free Forgings as stipulated in Technical Standards | |||||

| Temper | Direction | Tensile strength Rm/MPa | Prescribed plastic elongation strength Rp0.2/MPa |

Elongation A (%) |

|

| Free forgings | T6 | Portrait | 365 | ï¼ | 9.0 |

| T6 | Long transverse | 345 | ï¼ | 6.0 | |

| Die forgings | T6 | Portrait | 380 | 275 | 11.0 |

| T6 | Long transverse | 365 | 245 | 7.0 | |

| Tensile Properties of 2A50 Aluminum Alloy Forgings Stabilized at Room Temperature | ||||

| Temper |

Stabilization treatment |

Tension strength Rm/MPa |

Elongation A (%) |

|

| Temperature/â | Holding time /h | |||

| T6 | 20 | ï¼ | 392 | 12 |

| 200 | 0.5 | 275 | 15 | |

| 100 | 221 | 18 | ||

| T6 | 250 | 0.5 | 177 | 16 |

| 100 | 98 | 35 | ||

| 300 | 0.5 | 103 | 23 | |

| 100 | 64 | 45 | ||

The time interval between solution quenching and aging strengthening of 2A50 aluminium alloy should be less than 6 h, the overburning temperature should be 545 â, and the forging temperature should be 470-370 â.

| Type | Alloy | Projected areaï¼m2ï¼Or weightï¼kgï¼ | Temper | Standard |

| Free forgings | 5 series | ≤3000kg | OãF |

GBn223 ASTMB247 |

| 2ã6ã7 series | ≤3000kg | T6ãT4ãOãF | ||

| Mould forgings | 5 series | ≤2.5m2 | OãF | |

| 2ã6ã7 series | ≤2.5m2 | T6ãT4ãOãF |