2A14 is a high strength forged Al-Cu-Mg-Si alloy, which can be heat-strengthened. From the point of view of chemical composition and properties, it can belong to hard aluminium alloy and

forged aluminium alloy. It differs from

2A50 forged aluminium alloy in that the copper content of the alloy is more than double that of 2A50 alloy. The strength of the alloy after solution treatment and artificial aging is higher than that of 2A50, but its corrosion resistance is general and worse than that of 2A50. There is a tendency of intergranular corrosion and stress corrosion under artificial aging. The plasticity of the alloy is moderate, and the plasticity is not as good as that of 2A50 under hot condition. It has extrusion effect, indicating that the longitudinal and transverse properties of the alloy are different. It has good weldability and is suitable for resistance spot welding and seam welding. Its machinability is good.

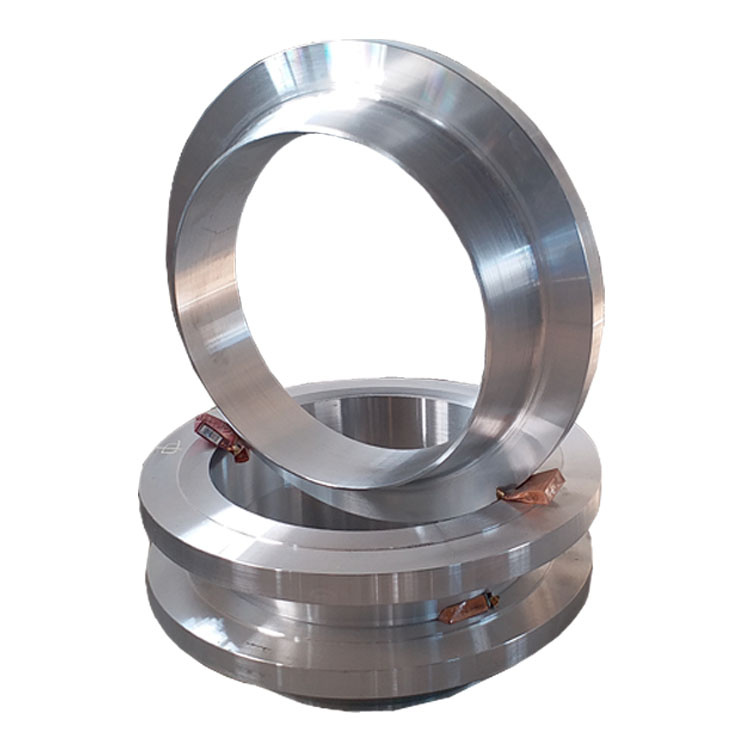

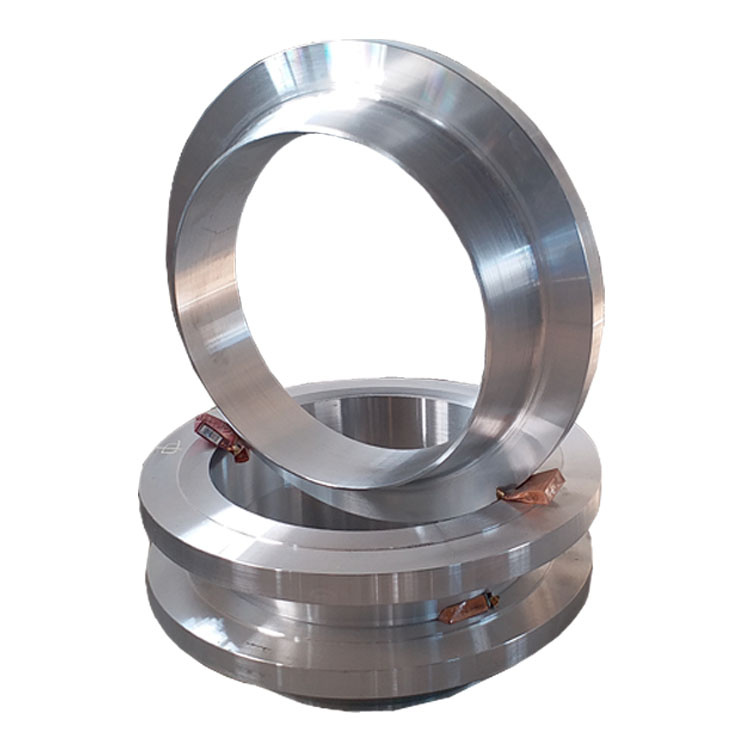

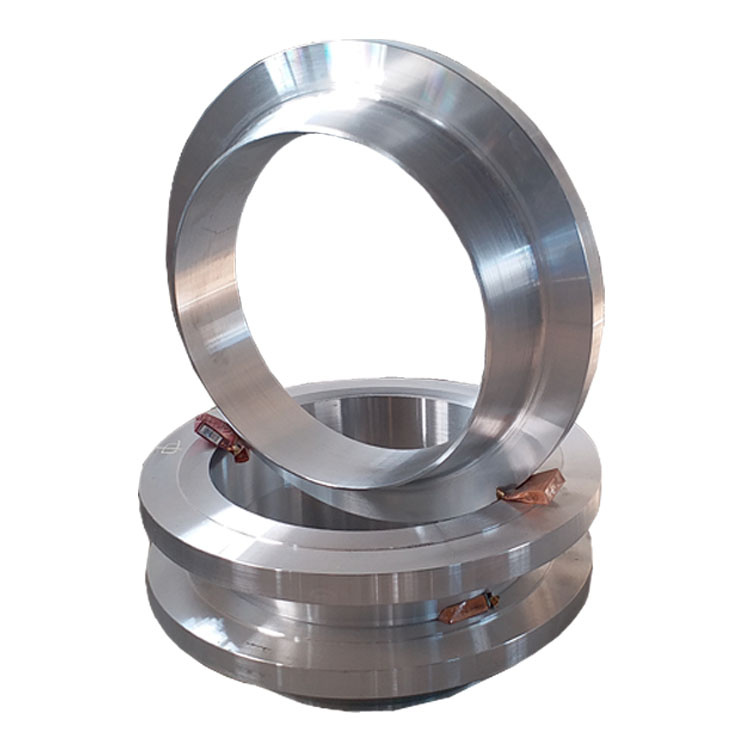

2A14 aluminium forgings

2A14 aluminium forgings alloy is used to manufacture free forgings and die forgings under high loads, as well as large frames, bridges, large shells, truck components, etc. However, due to the difficulty of hot pressing, the application range of the alloy is limited.

|

2A14 Mechanical properties of die forgings and free forgings |

|

|

Temper |

Direction |

Tension strength Rm/MPa |

Prescribed plastic elongation strength Rp0.2/MPa |

Elongation A

(%) |

|

Free forgings |

T4 |

Portrait |

380 |

245 |

10 |

|

T6 |

Portrait |

410 |

ï¼ |

8 |

|

Die forgings |

T4 |

Portrait |

380 |

245 |

11 |

|

T6 |

Portrait |

430 |

315 |

10 |

|

Tensile Properties of 2A14 Die Forging and Free Forging at Room Temperature |

|

|

Temper |

Dimension/mm |

Tension strength Rm/MPa |

Prescribed plastic elongation strength Rp0.2/MPa |

Elongation A

(%) |

|

Die forgings |

T6 |

≤50 |

450 |

385 |

6 |

|

>50--76 |

450 |

380 |

6 |

|

>76--100 |

435 |

380 |

6 |

|

Free forgings |

T6 |

L |

50--76 |

440 |

385 |

8 |

|

L-T |

440 |

380 |

3 |

|

S-T |

425 |

380 |

2 |

|

Room temperature hardness: Brinell hardness of 2A14 alloy in O state is 45 HBW, Bush hardness in T6 state is 135 HBW. |

|

Tensile Properties of 2A14 Aluminum Alloy Forgings Stabilized at Room Temperature |

|

Temper |

Stabilization treatment |

Tension strength Rm/MPa |

Prescribed plastic elongation strength Rp0.2/MPa |

Elongation A

(%) |

|

Temperature/â |

Holding time/h |

|

T6 |

130 |

10 |

510 |

431 |

7 |

|

100 |

520 |

422 |

8 |

|

1000 |

520 |

431 |

8 |

|

T6 |

150 |

10 |

500 |

451 |

8 |

|

100 |

495 |

456 |

7 |

|

1000 |

490 |

441 |

8 |

|

Type |

Alloy |

Projected areaï¼m2ï¼Or weightï¼kgï¼ |

Temper |

Standard |

|

Free forgings |

5 series |

≤3000kg |

OãF |

GBn223

ASTMB247 |

|

2ã6ã7 series |

≤3000kg |

T6ãT4ãOãF |

|

Mould forgings |

5 series |

≤2.5m2 |

OãF |

|

2ã6ã7 series |

≤2.5m2 |

T6ãT4ãOãF |