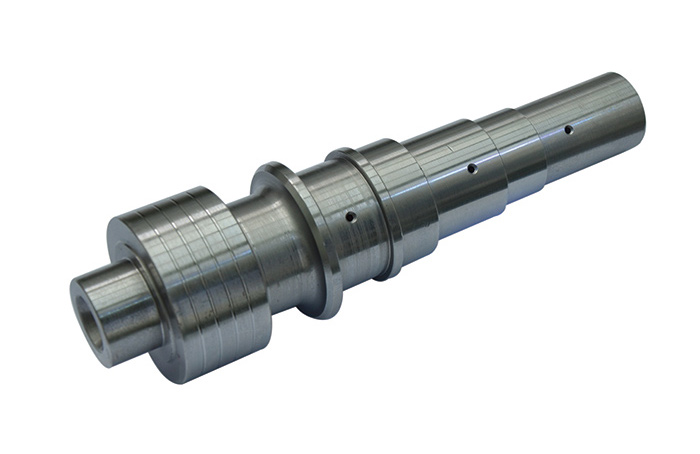

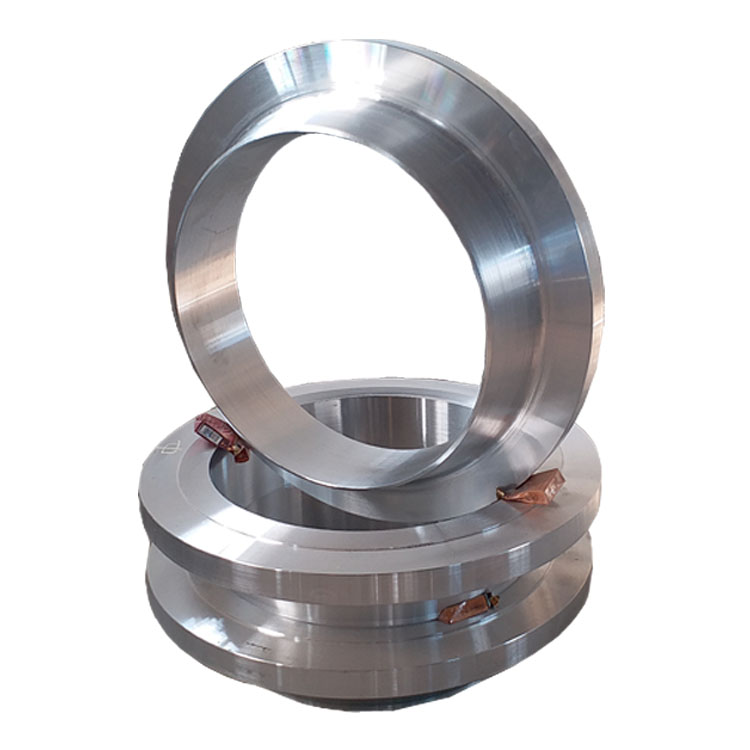

2014 Aluminum forgings forged product parts

2014 is a high strength forged Al-Cu-Mg-Si alloy, which can be strengthened by heat treatment. The chemical composition of the alloy is similar to that of 2114 aluminium alloy. It has high strength, good hot working property and is easy to forge. The performances are basically the same as 2114. Because of the high copper content, the alloy has poor corrosion resistance, intergranular corrosion and stress corrosion tendency. It has good weldability and cutting performance.

2014 is used to manufacture wheel rings with high strength, high hardness and high load, such as wheel rings, truck frame and suspension assembly, fuel tank and structural parts of rocket booster, etc. It can also produce 2014 coated aluminium material to improve its corrosion resistance.

| High Temperature Tensile Properties of 2014 Aluminum Alloy at Different Temperatures | ||||

| Temper | Temperature/â | Tension strength Rm/MPa | Prescribed plastic elongation strength Rp0.2/MPa |

Elongation A (%) |

| T6 | 100 | 439 | 393 | 15 |

| 150 | 276 | 241 | 20 | |

| 204 | 110 | 90 | 38 | |

| T6 | 260 | 66 | 52 | 52 |

| 315 | 45 | 34 | 65 | |

| 370 | 30 | 24 | 72 | |

In heat treatment of 2014 aluminium alloy, the suitable temperature of coolant for thin-walled parts with complex structure (wall thickness less than 30 cm) is 60-80 â. This process parameter can avoid deformation or warping of parts during quenching.

In heat treatment of 2014 aluminium alloy, the suitable temperature of coolant for thin-walled parts with complex structure (wall thickness less than 30 cm) is 60-80 â. This process parameter can avoid deformation or warping of parts during quenching.

The alloy has good plasticity in hot state and can be used to manufacture short sword and die forgings with complex shapes. The formability is poor in cold condition, and the forging temperature usually ranges from 440 to 320 â

| Type | Alloy | Projected areaï¼m2ï¼Or weightï¼kgï¼ | Temper | Standard |

| Free forgings | 5 series | ≤3000kg | OãF |

GBn223 ASTMB247 |

| 2ã6ã7 series | ≤3000kg | T6ãT4ãOãF | ||

| Mould forgings | 5 series | ≤2.5m2 | OãF | |

| 2ã6ã7 series | ≤2.5m2 | T6ãT4ãOãF |